When you take an elevator in a high-rise office tower or a posh apartment, you want speed, a quiet ride, and a smooth ride. But what is the elevator like on an oil rig? Or in a chemical processing facility with volatile chemicals? In those cases, elevators are not just taking you to a new level; they are stopping a loss of life or infrastructure from happening.

Here comes the Flameproof Elevator.

In this blog, we will describe what are flameproof elevators and where are they required, and why they are so important in different industries.

What Are Flameproof Elevators and How Do They Work?

A flameproof elevator is designed for dangerous locations where an explosion might take place. Here, flammable gases or vapors, dust, or chemicals are present in the atmosphere. It is designed to protect against an internal explosion. Some features enable the containment of one. It prevents sparks or flames from emanating from within the elevator that could otherwise ignite an explosive chain reaction.

How do they operate?

Electrical Components Encapsulated: Every motor, control panel, and switch is enclosed in an explosion-proof enclosure.

Pressure-Resistant Enclosure: Any internal ignition won’t have an impact on the surrounding environment thanks to the flameproof casing.

Intrinsically Safe Wiring: Even in the event of a fault, the entire electrical wiring system is built to prevent sparking.

Ventilation systems: They stop it from getting too hot and maintain fire safety.

Flameproof elevators provide a reliable elevator option for the elevator industry in a hazardous environment due to the engineering materials.

Key Safety Features of Flameproof Elevators

The emphasis of flameproof elevators is on protection as well as prevention, and differs from traditional industrial elevators in the following areas:

- ATEX & IECEx compliant, as identified by international law, ensures safety for explosive atmospheres.

- Anti-Static construction: Reduces the probability that an electrostatic discharge will ignite.

- Junction boxes that are flameproof contain all electrical connections to avoid exposure.

- Enclosure for Explosion Protected Lifts: To increase strength and resistance to corrosion, materials like reinforced aluminum or stainless steel are utilized.

- In the event of a gas leak, integrated gas detectors can be installed to automatically stop the elevator.

Flameproof Elevators for Hazardous Environments

To be clear, not all risk of disaster = Hazard. While industries have the potential to be safe and operate very well in the long term with the right precautions.

- Employee Safety: Your employees are your biggest asset. Traditional lifts are dangerous in an explosive atmosphere.

- Asset Protection: One spark could cause enough damage to the infrastructure, machinery, and chemicals to be worth crores.

- Legal compliance: Companies in regulated industries have no option but to comply.

- Continuity of Operations: Every hour of interruption from unsafe safety hazards can equate to hundreds of thousands of rupees. Flameproof lifts help minimize risk and maximize uptime.

These are some of the benefits of using explosion-proof elevators in hazardous zones: protection of life, property, and uninterrupted operations.

Industries Governed by Legal Obligations of Flameproof Elevators

Under safety regulations around the world, many industries are obligated to have explosion-proof or flameproof lifts. Among the most common industries:

- Refineries for Oil and Gas

- Chemical Manufacturing Units

- Pharmaceutical Plants

- Ammunition Factories

- Mining Sites

- Explosive Storage Warehouses

- Paint and Coating Facilities

- Fertilizer Plants

Regulations often reference ATEX elevators or equivalent standards in the U.S. and India.

Flameproof Lift Applications in Oil and Gas Sector

When it comes to explosive gases like butane, propane, and methane, oil and gas facilities are among the most dangerous areas. Massive fire risks can result from a single, exposed electrical spark.

Why are they crucial in this situation?

- persistent presence of volatile vapors and gases.

- Failed mobility solutions are necessary for offshore and remote rigs.

- Petroleum safety authorities enforce regulations.

In addition to meeting safety regulations, flameproof lift applications in the oil and gas industry guarantee continuous operations, which is essential in high-output settings.

Utilization in Pharmaceutical and Chemical Facilities

Volatility is common in chemical processing facilities. Chemical reactions or explosions can result from even the smallest electrical safety error.

Pharmaceutical environments also deal with alcohol-based solvents and volatile substances during production. In these cases:

- Explosion proof elevators prevent ignition.

- Fire-resistant elevators safeguard people during emergencies.

- The use of ATEX elevators ensures international compliance.

These are the best elevators for chemical and petroleum industries, where both precision and safety are non-negotiable.

Role in Mining and Underground Operations

Underground mines are complex ecosystems. Methane, hydrogen sulfide, coal dust, and other flammable elements are present in high concentrations.

Installing hazardous area elevators in these locations is crucial for:

- Transporting workers and equipment safely.

- Managing emergency evacuations.

- Preserving functionality in harsh environments such as dust, heat, and moisture.

To address the unique requirements of underground use, explosion protected lifts are made with moisture-proof components and anti-corrosion materials.

Applications in Explosive Warehousing and Storage Units

From fireworks factories to gunpowder storage units, the threat of accidental ignition is a constant danger.

Here, elevator for explosive zones must:

- Meet the highest standard of electrical insulation.

- Include anti-static materials.

- Integrate manual overrides for emergency access.

Storage may seem passive, but the risks are active and real. A flameproof elevator helps keep this controlled.

Flameproof Elevators in Defense and Ammunition Factories

Defense infrastructure, especially those dealing with weaponry and ammunition, must meet the most stringent safety regulations. Here’s how flameproof elevators serve:

- Safe transport of heavy artillery and materials.

- Controlled internal systems that don’t interfere with electronic devices.

- Added insulation and grounding to prevent electromagnetic interference.

No compromise is acceptable when it comes to national security or personnel safety.

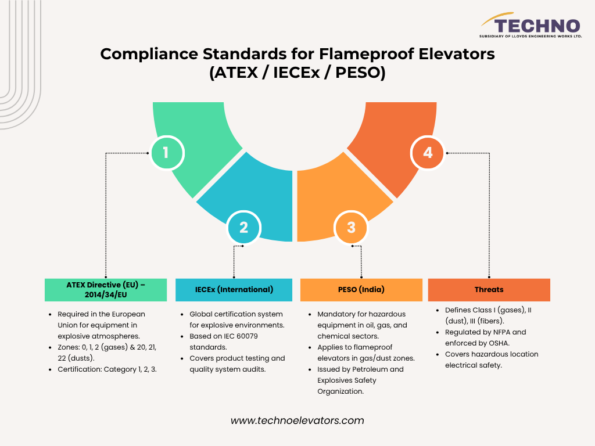

Compliance Standards and Certifications for Flameproof Elevators

Any flameproof or explosion-proof elevator must pass certifications under regulatory bodies. In India and globally, some of the main certifications to look out for include:

- ATEX Directive: Europe

- IECEx Certification: International

- PESO – Petroleum and Explosives Safety Organisation: India

- BIS/ISI Compliance for local safety norms

Ensuring your flameproof lift complies with these standards is non-negotiable.

Installation Guidelines for Flameproof Elevators

Installing a flameproof elevator isn’t the same as installing a regular lift. Here’s what you need to account for:

- Hazardous Area Classification (Zone 0, 1, or 2)

- Certified Materials & Components only

- Ventilation and cooling are adapted to the environment

- Surge Protection and Grounding

- Must be installed by trained personnel familiar with fire-zone operations

We recommend conducting a Hazard Risk Assessment before finalizing the elevator model.

Advantages of Conventional Elevators in Hazardous Areas

The following succinctly outlines the advantages of utilizing explosion-proof elevators in dangerous areas:

- Fire Safety: Designed to inhibit and contain explosives and fire.

- Longer Life: Environmentally, materials are exposed to corrosion, allowing them to last longer.

- Zero Spark Risk: Systems that are inherently safe have zero ignition sources.

- Reassurance: Reduce liability; protect property; guarantee worker safety.

- Compliance: Built to international safety standards, avoiding fines and closures.

To put it briefly, these are risk reducers rather than luxuries.

Final Take

Despite not being readily apparent to the general public, flameproof elevators have a vital and occasionally life-saving impact. Even though it’s simple to ignore them when creating a budget, neglecting safety in dangerous situations can have far more negative long-term effects on both the economy and people.

Installing a flameproof elevator is not just about compliance; it’s about responsibility, regardless of your industry: petroleum, pharmaceutical, mining, or defense.

Techno Elevators is more than just an elevator manufacturer. We create safety systems that are specifically designed for sectors that cannot afford to fail.

Speak with our flameproof systems specialist right now if you’re establishing a new facility or planning an upgrade.