By Techno Industries: Elevating Reliability Since Day One

Introduction

Elevators are the quintessential mode of vertical transportation, whether it be in transit stations, malls, hospitals, or high-rise apartments. Elevators are “vital organs” of building movement, but need to be constantly maintained.

Neglecting elevator maintenance invites breakdowns, risks to safety, and code violations. In this guide, we will examine each important aspect of the elevator maintenance and repair management process, from checklists and inspections to costs and technology, that will equip you to maintain the lift system at a normal level of operation, safety, and readiness for the future.

1. The Criticality of Compromised Elevator Maintenance for Safety and Code Compliance.

All elevators use a combination of software, electronics, and mechanics to operate. If any of these systems fail, safety becomes compromised.

Why practice unsafe elevator maintenance?

Passenger Safety:

Whether hundreds of passengers or thousands of passengers, elevators move people on a single trip every day. Dangerous conditions could result from a malfunctioning door sensor or cable misalignment.

Code Compliance:

GMP is no exception to having strict code compliance, namely the safety inspection and code regulations set by the Gujarat Government. The potential for civil and criminal penalties, and at the very least for not being fully compliant, is significant.

Extend Equipment Life:

Regular elevator maintenance reduces wear and tear and lessens the likelihood of prematurely replacing equipment.

Ride Quality:

All things equal, elevators that are well maintained will provide consistent wait times, riders will not feel odd or non-synchronized movement, and no additional interruptions in service.

2. Preventive vs. Corrective Elevator Maintenance Types

Not all elevator upkeep is made equal. They differ in the following ways:

- Preventive elevator upkeep: The purpose of this routine care is to stop issues before they start. Lubrication, cleaning, adjusting, and proactive part replacement are among the tasks.

- Corrective maintenance is the process of fixing or swapping out damaged parts, rewiring circuits, or regaining functionality after a failure.

Preventive maintenance elevators is less disruptive and more economical. Consider it an examination of your building’s mobility system.

3. Important Considerations to Look for during Maintenance

Although your elevator seems simple, there are many factors that you should check on a regular basis:

- Shaft and Hoistway Conditions: Dust, foreign materials, or leaks will add to damaging and rough rides.

- Traction System: Pulleys, ropes, and motors are the main components in elevator propulsion.

- Door Components: Accessors, sensors, rollers, and closures must all be aligned and responsive to operation.

- Control Panel and Software: Software bugs can create unwanted behaviors and misalignment.

- Emergency Features: Intercoms, back-up power, and alarms must all work at any time.

A dedicated elevator maintenance checklist would include all of these features and assist in identifying hazards before they materialize into disasters.

4. Typical Elevator Issues and Their Solutions

Let’s examine some common elevator problems and how to fix them:

Door not closing correctly: worn rollers or misaligned sensors could be the cause.

Fix: During service, realignment, or replacement

Jerky Movement: Possible Cause: Decreased lubrication or worn traction cables.

Solution: Scheduled lubrication and cable replacement

Overheating Motor: Ventilation block or excessive motor use can be the possible cause.

Fix: Increase cooling, service motor parts

Noisy Operation: Outdated or loose parts could be the cause.

Fix: Replacing components or tightening fittings

When regular diagnostics and the expertise of a qualified technician are combined, elevator repair becomes smooth.

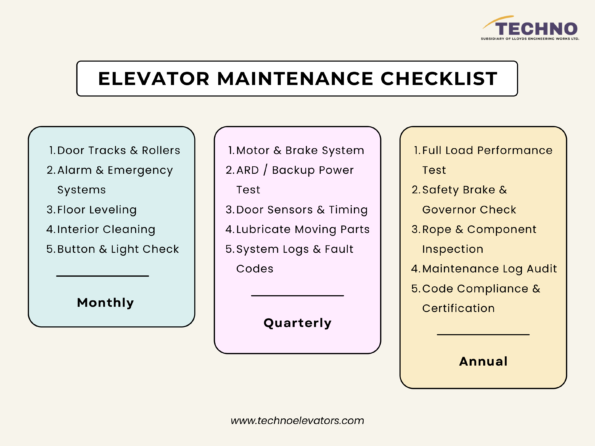

5. Schedules for Maintenance: Weekly, Monthly, and Annual Inspections

A well-planned schedule guarantees peak performance. This is a useful breakdown:

1. Checks every week: emergency lights

- Pit and shaft cleanliness

- Tests of door operation

2. Checks Every Month:

- Key component lubrication

- Sensor and safety brake testing

- Examination of the quality of the ride

3. Annual Examination:

- Complete electrical testing

- Alignment of structures

- Software updates and load testing

Maintaining your lift system’s readiness for the future and the importance of regular elevator inspections depend on your adhering to such schedules.

6. How to Pick a Trustworthy Elevator Repair Agency

Choosing the incorrect service partner can endanger lives in addition to costing money. Here’s what to assess:

- Certifications and Compliance Knowledge: Look for a team that has experience with local and federal regulations.

- Emergency Response Time: Can they handle being in the middle of a hospital elevator failure at 2:00 am?

- Flexibility: Every customer, whether commercial, industrial, or residential, has different variables.

- Client References: There is nothing more powerful than a recommendation from someone who uses the contractor’s service on a daily basis, particularly if that contractor has a good reputation and track record of success.

When searching for ‘Elevators Maintenance Services in Ahmedabad’, give top priority to companies that provide advanced diagnostic equipment, trained personnel, and transparent reporting.

7. Elevator Maintenance Management Digital Tools

Technology is changing the way elevator management is done. The digital age is here with IoT sensors and cloud-based maintenance logs.

Some of the most innovative platforms that are available today include:

Reporting Via the App:

Review any elevator maintenance history and everything the technician inputs, including any notes and inspection dates, in real-time. Remote Monitoring: Get prior warnings of malfunctions before they become an emergency.

Predictive Maintenance AI:

Increases lifecycle planning while decreasing maintenance-related downtime and unscheduled interruptions.

Elevator management is changing, and it is economically viable and provides service improvement.

8. Elevator Repair Costs: What to Expect and Budget For

Elevator repair costs depend on:

- Age of the system

- Type (hydraulic, traction, MRL)

- Parts needed (motors, controllers, cab interiors)

- Downtime loss

Have a preventive maintenance elevators contract. It reduces sudden repair bills and allows for better budget forecasting.

Most commercial buildings allocate 1.5-2% of the elevator’s capital cost annually toward maintenance. A wise investment for seamless operation.

9. Upgrade Old Elevators: When Repair Isn’t Enough

Sometimes, fixing isn’t fixing, it’s delaying the inevitable.

1. Signs your lift needs more than repair:

- Frequent breakdowns

- Long wait times

- Outdated controls or poor energy efficiency

- Safety compliance issues

2. Benefits of Upgrading:

- Faster operation

- Smart destination control

- Energy savings

- Enhanced safety features

At Techno Industries, we help modernize systems without disrupting operations—a must for housing societies, hospitals, and commercial complexes seeking to upgrade aging infrastructure.

10. Elevator Downtime Management: Keeping Tenants Informed

Downtime is inevitable. Mismanagement is optional.

Keep stakeholders informed with:

- Clear Notices: In advance for planned maintenance

- Real-Time Updates: Use digital displays or SMS alerts

- Quick Turnarounds: Choose service partners with fast repair cycles

This builds tenant trust and maintains your property’s reputation.

11. Regulatory Standards and Inspection Requirements

Every city has unique compliance mandates. For example, in Ahmedabad:

- Elevators must be inspected annually by certified officials

- Emergency safety systems must meet the Bureau of Indian Standards.

- Records of elevator inspection and maintenance must be maintained

Failing to follow these can result in penalties or shutdown orders. Staying compliant is part of being a responsible builder or facility owner.

12. DIY Elevator Maintenance: What Building Owners Can and Can’t Do

While basic visual checks can be done in-house, certain tasks are strictly for licensed professionals.

What you can do:

- Report unusual noises or delays

- Ensure the machine room is clean and dry

- Keep door sensors free of obstructions

What you shouldn’t do:

- Tinker with the control panel

- Lubricate components

- Open shaft doors or enter the pit

Elevator safety isn’t DIY territory. Stick to a professional team that handles lift maintenance with precision and expertise.

ELEVATOR MAINTENANCE CHECKLIST

Final Take:

The elevator service is more than just another vehicle for vertical transportation; think of it as the long-term value of continued use, the assurance of safety, and the presence of the building. Investing in professional Elevators Maintenance Services in Ahmedabad is not about the importance of now; it’s about future-proofing your property, long-term service, necessary upgrades, and reducing downtime from unexpected disruptions.

At Techno Industries, we don’t just want you to move; we want you to move with confidence. Whether you are the builder of a luxury home or the future decision makers of large societies, we are proud to partner with you in making every floor accessible, every ride uneventful, and every system safe.

Choose your maintenance, not as a task, but as an approach. You are responsible for your elevator’s performance tomorrow based on what you do to service it today.