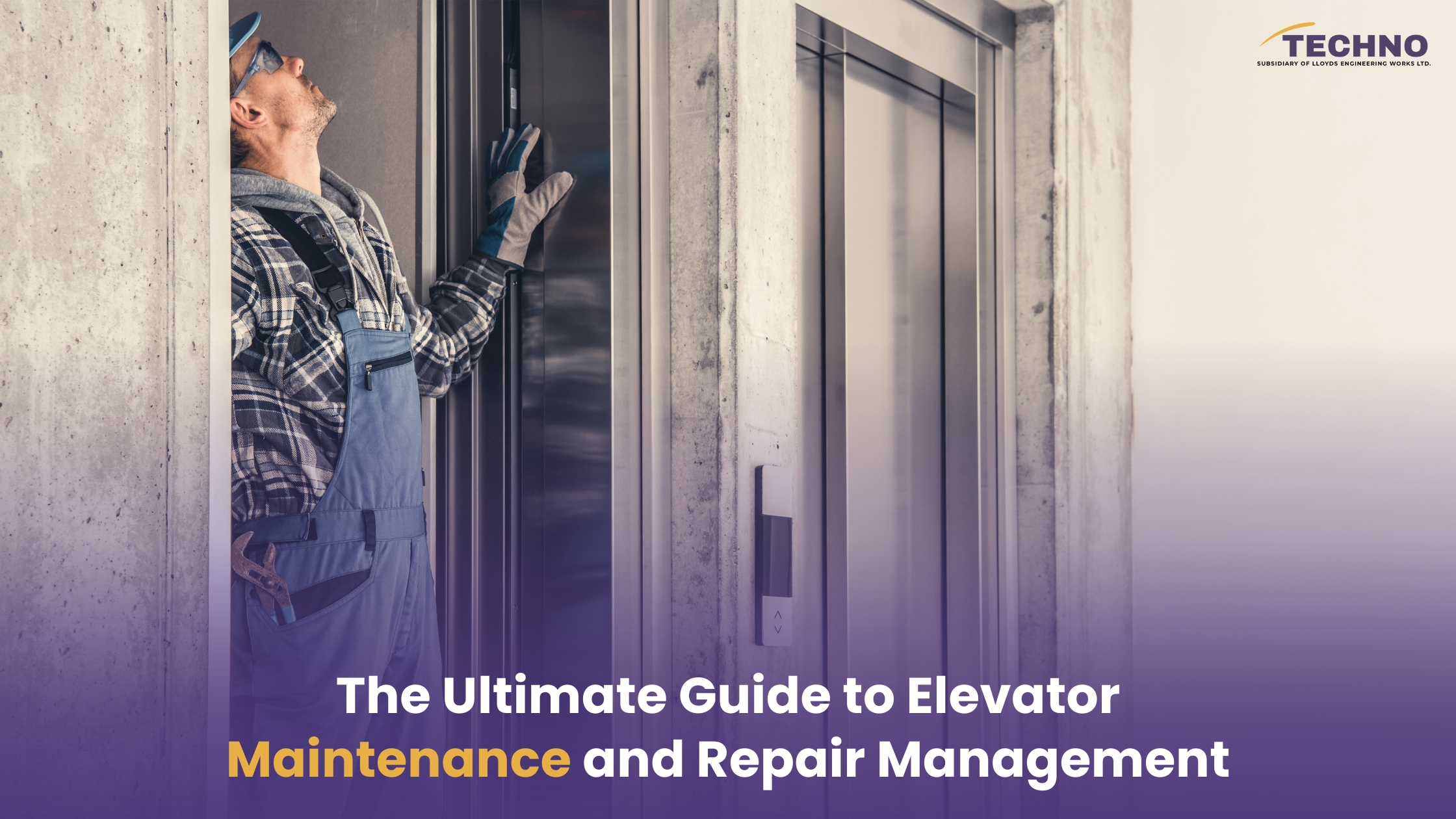

An elevator is one of those systems that most people only consider when it breaks down. However, if you’re involved in any aspect of construction, facility management, or urban development, you know differently. A poorly maintained lift does not simply use time but presents liabilities. It can greatly impact the usable area of a building, reduce safety, and in many cases, increase long-term costs far greater than anticipated.

So what is involved in an Elevator Maintenance Service? What does a standard visit involve? What is involved with a hydraulic lift service versus a traction elevator versus a high-speed vertical transport?

This blog will explore these questions, using experience, manufacturer’s guidance, and industry standards to bring you a sharply defined and actionable overview of proper elevator servicing, especially when it is more critical than ever.

The Importance of Lift Maintenance Company

Maintenance is not just about keeping the elevator functioning. It is about keeping the elevator functioning well for years, even decades. Maintenance is about keeping the elevator functioning well, smoothly, silently, and safely. Inadequate maintenance creates unnecessary wear and tear and subsequently, an excessive total maintenance cost over the long haul.

Whether you have a residential complex or are building a hospital, staying compliant with your maintenance by signing an elevator maintenance contract is a wise choice. Upkeep will always include considerations around uptime, passenger comfort, compliance, and ultimately value.

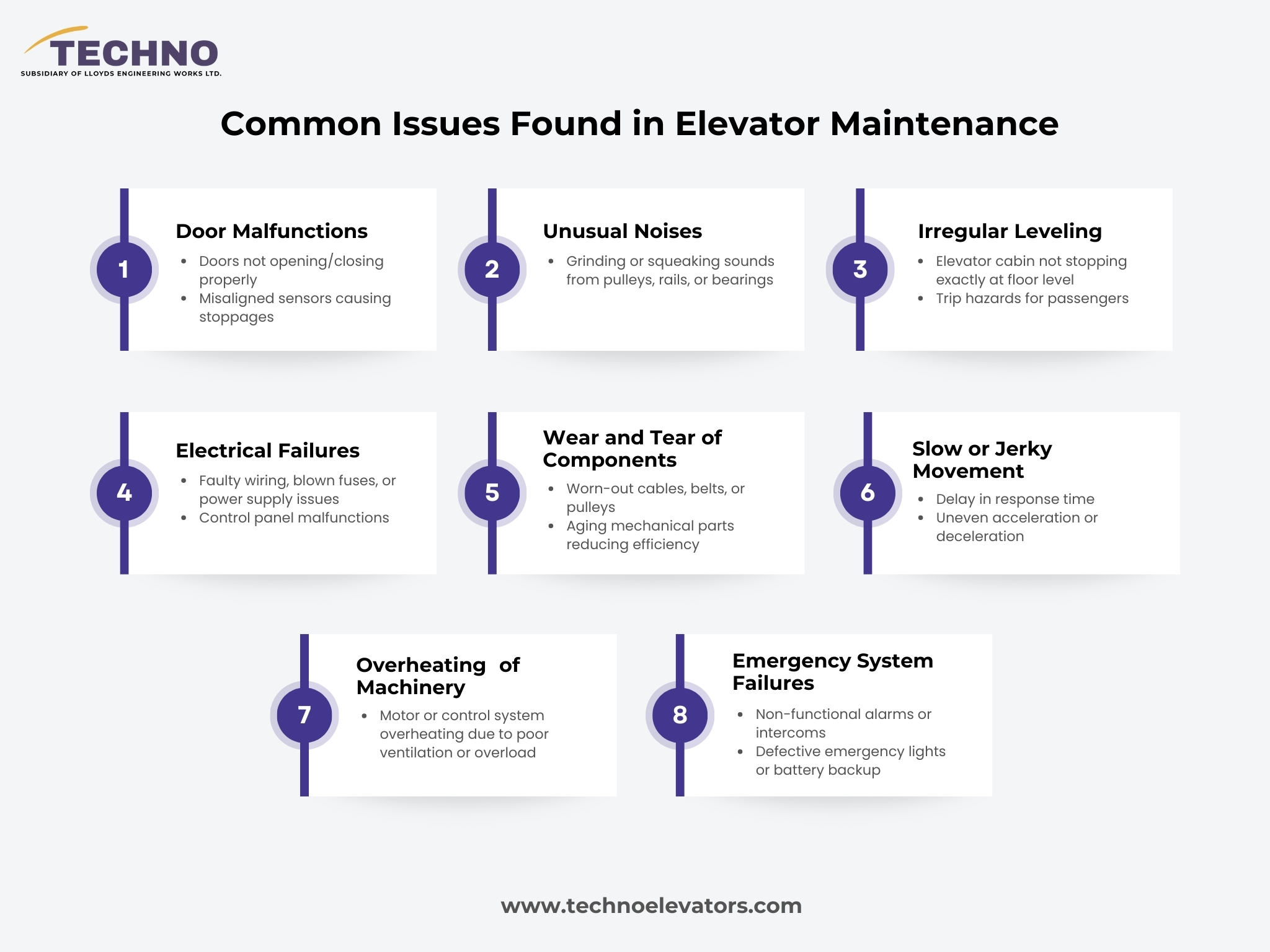

Common Issues Found in Elevator Maintenance

What is included in an elevator maintenance service?

Elevator maintenance services typically can include many elements, but the means of elevator service vary for different types of elevators, specifically the usage of the elevator and the environment surrounding said elevator.

1. Mechanical & Operational Inspection

Every service begins with a thorough visual and operational inspection. The inspection includes:

- Checking how doors operate

- Inspecting roller guides and guide rails

- Listening to and feeling for noise, vibration, and ride quality

- Assessing the performance of the motor and confirming the brakes’ functionality

- Lubricating moving parts to reduce friction and noise

In the case of hydraulic lifts, more attention is paid to fluid levels, pressure settings, and possible leaks in the hydraulic cylinder or valve system. These features are important, as both load handling and smoothness of travel can be impacted.

2. Electrical & Control System Checks

All elevators are dependent on control panels and automation systems. Qualified elevator mechanics will check:

- Controller units and circuit boards

- Wiring, relays, fuses, and terminals

- Signal response

- Backup power

Control system failures are some of the most frequent reasons for lift breakdowns, making this inspection step in any commercial elevator maintenance program so important. No business wants to interrupt their customers’ day with a breakdown that could’ve been prevented! Delegates hundreds of people during the day!

3. Safety Verification and Compliance Audit

Safety is not just about eliminating failures; it is part of the risk management process. A complete elevator inspection service includes:

- Testing emergency stop switches

- Testing alarm and intercom systems

- Testing overspeed governors

- Testing safety brakes and buffers

- Testing all fire safety integrations, if applicable

These elevator safety checks allow the lift to achieve compliance with local codes and global best practices.

4. Cleaning and Preventive Maintenance for Elevators

Dust, debris, and environmental exposure will constrain system efficiency. Technicians clean:

- Machine room

- Shaft pits

- Landing doors and sills

- Ventilation systems

Cleaning and preventative maintenance are particularly crucial for lift maintenance companies working on high-dust sites or coastal sites, due to the increased risk of wear from environmental exposure.

Lift Maintenance: What to Look For

If you are managing a facility or construction project, you’re probably not doing much of the maintenance yourself, but you should understand what is involved. Below you will find a brief lift maintenance checklist to keep in mind while reviewing the service.

- Cabin positioning and door sensors

- Control panel operability

- Oil levels – hydraulic lifts only

- Braking system

- Shaft and pit cleanliness

- Battery backup operations

- Ride quality and noise level

- Documentations and Service logbook

These checkpoints will help you verify that your lift servicing team is covering important aspects and not just going through the motions.

Preventive Maintenance for Elevators: The Intelligent Choice

Preventive maintenance on elevators is not an option; it’s the industry standard. Continuing the use of scheduled service for your elevator will limit emergency breakdowns, increase the life of your components, and lower the costs of operating the elevator. Why wait until emergency service is needed when the elevator can have issues diagnosed or repaired before performance or safety is compromised?

With hydraulic lifts in particular, you have a system dependent on oil pressure and valve control. Any lagging or jerky feeling when the elevator is started could be an indicator of bigger problems to come. Catching those in the maintenance program will save a lot of elevator repair and maintenance costs for your elevators later.

Are AMC Services Worth It?

Yes, if done properly. A full elevator AMC service will cover all periodic inspections, safety inspections, lubrication, and minor repairs, all under one contract. You will have a predictable cost, and you can be assured your building is compliant with elevator regulations all year round.

For developers and societies that are managing multiple elevators, a reliable elevator maintenance contract is an investment that protects you from budget shocks and also the need to make last-minute panic repairs.

Factors Affecting Elevator Maintenance Costs

Costs depend on:

- Type and size of lift: hydraulic, traction, MRL, etc.

- Use frequency of residential vs. public transport

- Number of stops and floors

- Make and model of the system and its age

- Level of service: a basic service, or full-service AMC

Remember, the cost of elevator maintenance is, or should be, much less than the cost of replacement or major repairs – if performed consistently and done professionally. The economy of cutting corners today usually leads to unanticipated or unbudgeted costs tomorrow.

Why builders and facility managers should take servicing seriously

No one thinks about elevators when they have been working properly, and it is no problem for tenants, visitors, and regulators. When elevators aren’t working, tenants, visitors, and regulators take notice. It does not matter if you are building a luxury high-rise condominium building or managing a busy hospital; your elevator system will be an essential part of the experience of your users.

In the end, elevator maintenance service is not just about the machines. It’s also a reflection of your commitment to safety and usability, and your commitment to value over the long term.

Final Take

If your elevator system is over 10 years old and has not been a significant part of a regular maintenance plan, you should do something.

With the increase in vertical infrastructure construction, maintenance can no longer be viewed as optional; it is fundamental.

If you are looking to install hydraulic lifts in new homes, offices, or commercial complexes, your value of a predictive maintenance partner cannot be overstated.

As an elevator maintenance business, entrenched in the manufacturing of elevators, service, and modernization, we view elevators less as machines and more as lifelines that connect

Know More About Elevator Maintenance

By Techno Industries: Elevating Reliability Since Day One Introduction Elevators are the quintessential mode of vertical transportation, whether it be in transit …

Frequently Asked Questions

Elevators should typically undergo maintenance every 3–6 months. High-traffic buildings or older elevators may require more frequent servicing. Regular maintenance ensures smooth operation, safety, and reduces the risk of unexpected breakdowns.

Elevator maintenance should only be performed by trained and certified technicians. These professionals have the necessary expertise in mechanical, electrical, and safety systems to ensure the elevator operates reliably and safely.

Skipping regular maintenance can lead to mechanical failures, operational issues, or even safety hazards. Over time, worn-out components and neglected safety systems may result in costly repairs or accidents. Regular servicing helps prevent such risks.

Standard maintenance typically covers inspections, repairs, and preventive care. Modernization or upgrades—such as replacing control panels, installing energy-efficient systems, or adding advanced safety features—are separate services and need to be requested explicitly.